-

linha ondulada da extrusão da tubulação da parede dobro

-

Linha da extrusão ondulada da tubulação

-

linha de extrusão de tubos de PEAD

-

Linha da extrusão da tubulação de DWC

-

Linha da extrusão da tubulação dos PP

-

Linha da extrusão da tubulação do PVC

-

linha espiral da extrusão da tubulação

-

Linha da extrusão da tubulação da proteção do cabo

-

linha plástica da extrusão da tubulação

High Productivity HDPE Pipe Extrusion Line Including High Speed Automation and Pipe Diameter Range 32mm 1600mm Designed for Industrial

Contacte-me para amostras e cupons grátis.

Whatsapp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Se tiver alguma preocupação, fornecemos ajuda online 24 horas por dia.

x| Pipe diameter range | 32mm - 1600mm | Plastic Processed | PVC / PE / MPP / PA / HDPE |

|---|---|---|---|

| Used For | Making Plastic Corrugated Pipe Products | End Product | Plastic Pipe For Drainage, Sewage Discharge |

| Automation | Automatic And Computerized ,High Speed | Application | Water Supply, Gas Supply, Sewage, Drainage, Irrigation |

| Output | 100-2000kg/h | Cooling Type | Air Cooling And Water Cooling |

| Destacar | HDPE pipe extrusion line with automation,industrial HDPE pipe extrusion machine,HDPE pipe extruder 32mm-1600mm |

||

Product Description:

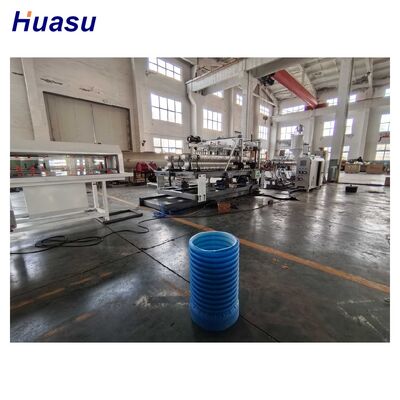

The corrugated pipe production line is the third generation of advanced machinery developed by Shandong HUASU. This newest model features substantial improvements in both output and production speed, achieving an increase between 20% and 40% compared to earlier versions.

Equipped with cutting-edge online belling technology, the production system ensures that the finished corrugated pipes possess superior performance characteristics. This innovation greatly enhances the quality and uniformity of the final products.

Additionally, the entire manufacturing process is managed by a sophisticated Siemens PLC system. This advanced control platform optimizes operational efficiency and guarantees consistent and dependable performance throughout the production line.

Features:

Introducing a newly designed closed molding machine that features a specialized high-efficiency cooling system, specifically engineered for aluminum modules. This innovation ensures optimal temperature control during the molding process, enhancing the quality and durability of the final product.

The production line includes a high-speed, high-output single-screw extrusion machine, equipped with a professional-grade corrugated pipe extrusion mold. This setup guarantees precision and consistency, meeting the demanding requirements of large-scale manufacturing.

Our interchangeable modules are crafted from premium LY12 alloy aviation aluminum, containing 5% copper. This composition provides exceptional strength and outstanding corrosion resistance, making it ideal for applications that require long-lasting performance.

Utilizing a precision pressure casting process, these modules resist deformation and effectively eliminate light pores, ensuring structural integrity and superior surface quality.

We also offer customizable waveform solutions tailored to meet diverse project needs, allowing for flexibility and adaptability in various industrial applications.

To complete the production process, a computer-controlled automatic chipless cutting machine is employed. This equipment provides precise positioning and stable operation, contributing to high accuracy and efficiency in the final output.

Technical Parameters:

| Output | 100-2000kg/h |

| Cooling Type | Air Cooling And Water Cooling |

| Pipe Application | Drainage, Sewage Discharge, Water Supply And Outdoor Water Supply |

| Plastic Processed | PVC / PE / MPP / PA / HDPE |

| Features | High Productivity, Competitive Price, Energy Saving, Automatic |

| Application | Water Supply, Gas Supply, Sewage, Drainage, Irrigation |

| Used For | Making Plastic Corrugated Pipe Products |

| Raw Material | PVC / PE / MPP / PA / HDPE Granules And Pellets |

| End Product | Plastic Pipe For Drainage, Sewage Discharge |

| Automation | Automatic And Computerized, High Speed |

Applications:

This Plastic Pipe Making Machine is designed to produce high-quality pipes that meet various application needs.

It is ideal for water supply systems, providing reliable and safe transportation of water in residential, commercial, and industrial settings.

Additionally, the machine produces pipes suitable for drainage systems, which facilitate efficient wastewater management.

Furthermore, these pipes serve as electrical cable conduits, offering protection and organized routing for wiring installations.

All pipes produced by this machine adhere to industry standards, guaranteeing outstanding durability and performance even in the most challenging environments.